home

> products

> BAT's

> BAT

species > BAT-2

BAT-2 zone-plate-focussed BAT®

Description:

The BAT-2 transducer employs a micromachined zone-plate to provide a tightly-focussed ultrasonic beam profile in air. Use of a zone-plate also allows the focal length of the probe to be altered simply by changing the frequency of operation (i.e., the focal point can be moved back and forth along the transducer axis). Two different versions are currently available: the first a low frequency version optimized for performance at 500kHz (option ZP5); and the second a higher frequency version optimized for performance at 1.5MHz (option ZP15). The nominal spot-size of the low-frequency version is 680µm Ø (at f = 500kHz) and its focal length can be shifted over a 5-15mm range. The nominal spot size of the high-frequency version is a mere ~200µm Ø (at f = 1.5MHz) and its focal length can be shifted over a 5-8mm range. Both versions of the MicroAcoustic BAT-2 transducer are typically operated in a toneburst mode. This transducer has proven particularly useful for non-contact surface imaging and metrology applications at the surfaces of liquids or solids (see the in-air/reflection application page - example A.1.b).

contact us >> for pricing & availability

Specifications:

- type: zone-plate focussed transducer

- focal spot size: 680µm Ø for ZP5, 200µm Ø for ZP15

- focal length: ~7.5mm (at design frequency), frequency dependent

- focal length range: 5-15 mm for ZP5 (400-900kHz), 5-8mm for ZP15 (1-1.5MHz)

- depth of field: 3mm for ZP5, 1mm for ZP15 (at design frequencies), frequency dependent

- useable ultrasonic bandwidth: 400-900kHz for ZP5, 1-1.5MHz for ZP15

- main housing dimensions: cylindrical, 34mm Ø x L 26mm

- electrical connector: gold MCX on rear of housing

- mounting: axial / transverse mounting via 1/4"-20 threaded housing mount

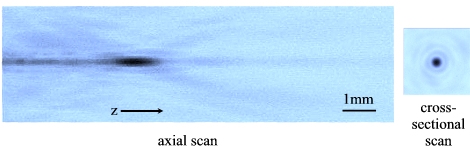

Typical beam profile:

These beam profiles were obtained experimentally for a BAT-2 source transducer (option ZP15) operating in air under toneburst excitation at a frequency of 1.5MHz. The images were obtained using MicroAcoustic's proprietary miniaturized scanning recievers. The left figure is an axial scan of the transducer whereas the right figure is a cross-sectional scan through the focus of the beam. Both figures plot the highest intensity as black with the lowest intensities light blue. In the axial scan (left figure), the ultrasonic beam emerges from the transducer at left, and exhibits some degree of sensitivity along axis before concentrating most of its energy at the dominant focal region at a distance of ~8mm from the aperture. The on-axis depth-of-field is approximately 1mm. The cross-sectional scan on right shows the inherent symmetry of the tiny ~200µm Ø spot size. Such a tiny spot size is very useful for high resolution surface imaging of materials without contact (as shown below).

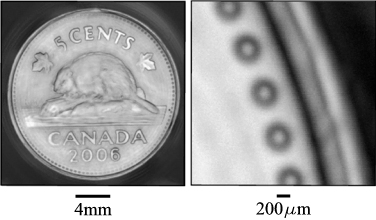

Typical imaging resolution:

The types of images that can be acquired at solid surfaces using a MicroAcoustic BAT-2 transducer in a non-contact mode are shown above for the surface of a Canadian "nickel". The left image is a 23x23mm area scanning the entire nickel surface and with unaveraged amplitude data being acquired on a 60µm square grid. The right image is of a 2x2mm area near the periphery of the nickel only and with unaveraged amplitude data being acquired on a 20µm square grid. In both scans, the higher-frequency version of the BAT-2 transducer was employed in a pulse-echo mode. The capability of this type of air-coupled transducer for high-resolution surface imaging is obvious from these scans, where in particular the ability to resolve the small bumps of 200µm diameter just inside the raised edge of the nickel is quite impressive. Combining such images with additional time-of-flight information would make these images even more impressive (see example A.1.a for a demonstration of this).

www.microacoustic.com