home > products

> BAT's

>

BAT

examples

> example B.1.a

Air-coupled through-thickness C-scan of a thin CFRP plate using BAT® transducers

The experiment:

The MicroAcoustic

BAT can be used to great effect for non-contact

Non-Destructive Testing (NDT) of

composite materials. In this example, two non-contact BAT-1

transducers were used in a  through-transmission C-scan arrangement

(see figure at right) in order to image defects and variations within a

thin carbon-fibre reinforced composite (CFRP) plate. The transducers in this case were placed a

distance of ~10cm apart in a coaxial configuration, and with the normal of

the plate parallel the transducer axes as shown. The source transducer was

excited into vibration using MicroAcoustic's

V-Pole and a ~400V

p-p toneburst voltage at frequency 685kHz. The toneburst frequency was

chosen so as to match to the nominal

through-thickness longitudinal resonance of the plate.

On the receive side, MicroAcoustic's

Q-Amp

transimpedance preamplifier was employed.

Because air-coupled inspection of composite materials is far more

practical than many people may know, it is important to mention that no signal processing or image processing

was required to obtain the results below.

through-transmission C-scan arrangement

(see figure at right) in order to image defects and variations within a

thin carbon-fibre reinforced composite (CFRP) plate. The transducers in this case were placed a

distance of ~10cm apart in a coaxial configuration, and with the normal of

the plate parallel the transducer axes as shown. The source transducer was

excited into vibration using MicroAcoustic's

V-Pole and a ~400V

p-p toneburst voltage at frequency 685kHz. The toneburst frequency was

chosen so as to match to the nominal

through-thickness longitudinal resonance of the plate.

On the receive side, MicroAcoustic's

Q-Amp

transimpedance preamplifier was employed.

Because air-coupled inspection of composite materials is far more

practical than many people may know, it is important to mention that no signal processing or image processing

was required to obtain the results below.

The sample:

The sample was a ~2mm thick, 16-ply quasi-isotropic CFRP plate with a

[0,+45,90,-45]2s fiber layup. Such a quasi-isotropic

layup places alternating layers of carbon fibers at 45° to one another

during manufacture. Within the sample were two carefully embedded defects:

the first was a 2.54cm square piece of 125µm thick Teflon tape, and the

second was a similarly sized brass shim. Such defects are often included in

composite test samples in order to simulate delaminations within the

material. In this case, the defects had been introduced in such a way as to

replace some of the central fibers, such that their existence was not

evident by visual inspection of the finished sample. Two impact damage sites

were also created in the finished panel by firing particles at high velocity

at the sample.

The resulting image:

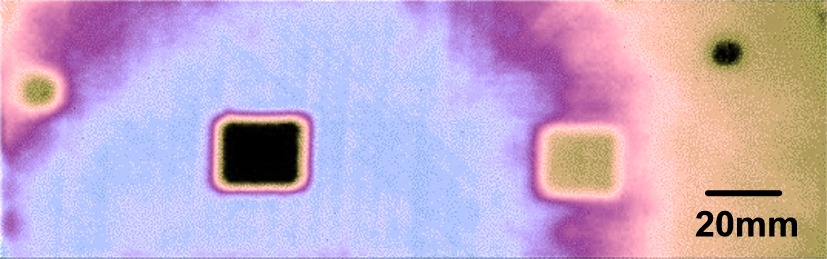

The resulting C-scan image above is typical of the excellent images that can be obtained by MicroAcoustic's BAT® transducers when investigating composite materials without contact. Unaveraged receive signal amplitude is here mapped (highest to lowest) according to blue, purple, brown, and then black. The slowly varying background (blue through brown) is a result of subtle thickness variations not evident by visual observation of the sample. The black square at left is due to the simulated delamination created by the embedded Teflon tape, while the brown square at right reveals the position of the embedded brass shim. The two circular spots (far-left and far-right) are the impact damage sites. Just visible in the blue-white region (at 45° intervals) are the fiber-orientations within the layup; these usually appear in air-coupled C-scans despite ultrasonic wavelengths being much larger than characteristic fiber dimensions.

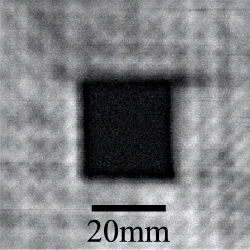

As

the above C-scan was acquired by an unfocussed BAT-1

transducer, the image resolution can be greatly improved by moving to the

use of a focussed BAT® transducer. This is demonstrated in the

grey-scale image at right, which is a rescan of the region surrounding the

Teflon defect only for the same 16-ply CFRP plate. Not only are the

fiber-orientations now much more clearly resolved to show their

quasi-isotropic layup, but the ends of the fibers are just becoming visible

where they meet the square Teflon defect. Also, the cut line of the

fiber-fabric is now starting to show that it departed from being perfectly

square (see the right hand edge of the defect in particular where the fabric

bows inward slightly, and also note the missing ~2mm square of fabric in the

top-right corner). This is nothing short of impressive and especially so

since it is obtained by completely non-contact air-coupled means.

As

the above C-scan was acquired by an unfocussed BAT-1

transducer, the image resolution can be greatly improved by moving to the

use of a focussed BAT® transducer. This is demonstrated in the

grey-scale image at right, which is a rescan of the region surrounding the

Teflon defect only for the same 16-ply CFRP plate. Not only are the

fiber-orientations now much more clearly resolved to show their

quasi-isotropic layup, but the ends of the fibers are just becoming visible

where they meet the square Teflon defect. Also, the cut line of the

fiber-fabric is now starting to show that it departed from being perfectly

square (see the right hand edge of the defect in particular where the fabric

bows inward slightly, and also note the missing ~2mm square of fabric in the

top-right corner). This is nothing short of impressive and especially so

since it is obtained by completely non-contact air-coupled means.

Conclusions:

1) This example shows that MicroAcoustic's BAT® transducers provide a practical non-contact alternative for the inspection and characterization of composite materials.

2) Thickness variations, delaminations, inclusions, impact damage and fiber-orientation can all be easily detected and imaged in polymer-based composite materials using the MicroAcoustic's BAT®.

3) Because of their wide bandwidths, BAT® transducers allow tuning of toneburst drive frequencies to match nominal through-thickness resonances of samples. This greatly improves signal-to-noise ratios, and makes rapid air-coupled inspection of composite materials possible without signal averaging.

4) Unlike other air-transducers available (which have much narrower frequency bandwidths), MicroAcoustic's BAT® transducers can be used with a wide variety of materials and material thickness without the need to change transducers. This saves time and money, since only one set of BAT transducers are required for most of your inspection needs.

<< previous example ~ next example >>

www.microacoustic.com