home

> products

> BAT's

> BAT

examples

> example B.1.d

Air-coupled C-scan of a thermoplastic composite plate using BAT® transducers

The experiment:

MicroAcoustic

BAT®

transducers provide a practical non-contact alternative

for Non-Destructive Testing (NDT) of thermoplastic composite materials. In this example, two non-contact BAT-1

transducers were used in a  through-transmission C-scan arrangement

(see figure at right) in order to image defects and variations within a

fiber-reinforced thermoplastic composite plate. The transducers were placed a

distance of ~10cm apart in a coaxial configuration, and with the normal of

the plate parallel the transducer axes as shown. The source transducer was

excited into vibration using MicroAcoustic's

V-Pole™ and a

~400V p-p toneburst voltage at frequency 387kHz. The toneburst frequency

was chosen so as to match to the fundamental through-thickness

longitudinal resonance of the plate. On the receive side, MicroAcoustic's

Q-Amp™

transimpedance preamplifier was employed. Because air-coupled inspection

of composite materials is far more practical than many people currently

know, it is important to point out that no

signal processing or image processing was required to obtain the results

below.

through-transmission C-scan arrangement

(see figure at right) in order to image defects and variations within a

fiber-reinforced thermoplastic composite plate. The transducers were placed a

distance of ~10cm apart in a coaxial configuration, and with the normal of

the plate parallel the transducer axes as shown. The source transducer was

excited into vibration using MicroAcoustic's

V-Pole™ and a

~400V p-p toneburst voltage at frequency 387kHz. The toneburst frequency

was chosen so as to match to the fundamental through-thickness

longitudinal resonance of the plate. On the receive side, MicroAcoustic's

Q-Amp™

transimpedance preamplifier was employed. Because air-coupled inspection

of composite materials is far more practical than many people currently

know, it is important to point out that no

signal processing or image processing was required to obtain the results

below.

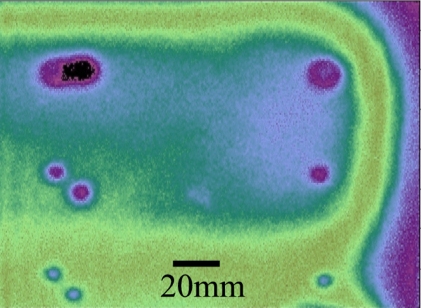

The sample: The sample was a specially constructed fiber-reinforced polymer composite plate having a thickness of 3.5mm. The carbon-fibers employed were in a quasi-isotropic lay-up and were embedded in a PEEK thermoplastic matrix. The use of thermoplastic as the matrix material is of interest since it can be reheated under pressure to correct any disbonding that might occur during manufacture. Within the sample were included various 100µm thick artificial circular defects in the form of graphite foil (or "graphoil"). Such foil acts as a form of delamination within the plate, since it reduces adherence of one layer in the laminate to the next. Three diameters of circular graphoil defect were used (1.5mm, 6mm and 12mm) some of which were placed at different depths within the sample. The positions of these defects within the plate cannot be seen from visual observations of the sample.

The resulting image:

The resulting C-scan image above is typical of the excellent images that can be obtained by MicroAcoustic's BAT® transducers when investigating fiber-reinforced thermoplastic composite materials without contact. Unaveraged receive signal amplitude is here mapped (highest to lowest) according to light-green, dark-green, light-purple, dark-purple, and finally black. The three singlet circles on the right side of the figure (arranged vertically), and the three sets of doublet circles on the left-side of the figure, mark the positions of the graphoil defects of different sizes contained within the plate. The graphoil defects serve to destroy (or partially destroy) the fundamental through-thickness resonance of the plate locally and so reduce the transmitted signal in those regions. The right-most graphoil circle within the largest doublet defect (top-left) has actually reduced the signal level down to the noise level (see black region). The otherwise gradual colour variations from the light-green areas to dark-green/light-purple area at center and from light green to dark purple at the extreme right edge are due to thickness variations of the plate which are just barely visible from visual inspection of the sample.

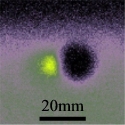

Any narrow bandwidth air-coupled

transducer whose center frequency happened to be ~387kHz would not be able

to proceed beyond acquiring an image like that shown above. The MicroAcoustic

BAT®

however, because of its wide bandwidth, can simply alter frequency and run  further

scans in order to obtain further information about the sample. As an

example, the image shown at right is a rescan for the largest doublet defect

region only, and was acquired at double the frequency of the scan above,

namely 774kHz. This frequency corresponds to the first harmonic of the

longitudinal through-thickness resonance in the normal region of the plate,

which is less strong than the fundamental but still provides

transmission

(see green and light purple areas at right). At this higher frequency, the

left-most defect of the doublet now almost doubles the strength of the

thru-transmission signal over the non-defective region of the plate, whereas

the right-most defect reduces thru-transmission to the noise level. This

different response of the two defects within

the largest doublet occurs because of the different depths

at which the two

defects had been placed within the plate: the left defect had been placed at the mid-plane

during manufacture, whereas the right defect was placed at a depth of one

quarter thickness. Being placed at the mid-plane of the plate, the left

defect divided the sample into two half thickness plates, each of which

could now respond at their common fundamental resonance frequency of 774kHz

(i.e., double the fundamental resonance of the full-thickness plate),

thereby increasing transmission signals in this region. The conclusion here

should be obvious: namely, that the use of greater bandwidth air-coupled sensors

will always provide greater information about your materials.

further

scans in order to obtain further information about the sample. As an

example, the image shown at right is a rescan for the largest doublet defect

region only, and was acquired at double the frequency of the scan above,

namely 774kHz. This frequency corresponds to the first harmonic of the

longitudinal through-thickness resonance in the normal region of the plate,

which is less strong than the fundamental but still provides

transmission

(see green and light purple areas at right). At this higher frequency, the

left-most defect of the doublet now almost doubles the strength of the

thru-transmission signal over the non-defective region of the plate, whereas

the right-most defect reduces thru-transmission to the noise level. This

different response of the two defects within

the largest doublet occurs because of the different depths

at which the two

defects had been placed within the plate: the left defect had been placed at the mid-plane

during manufacture, whereas the right defect was placed at a depth of one

quarter thickness. Being placed at the mid-plane of the plate, the left

defect divided the sample into two half thickness plates, each of which

could now respond at their common fundamental resonance frequency of 774kHz

(i.e., double the fundamental resonance of the full-thickness plate),

thereby increasing transmission signals in this region. The conclusion here

should be obvious: namely, that the use of greater bandwidth air-coupled sensors

will always provide greater information about your materials.

Conclusions:

1) This example shows that MicroAcoustic's BAT® transducers provide a practical non-contact alternative for the inspection and characterization of fiber-reinforced thermoplastic composite materials.

2) Delaminations (and their positions within a plate), inclusions, and thickness variations are but some of the features that can be easily detected and imaged in such composites using the MicroAcoustic's BAT®.

3) Because of their wide bandwidths, BAT® transducers allow tuning of toneburst drive frequencies to match to various through-thickness resonances of samples. This greatly improves signal-to-noise ratios, and makes rapid air-coupled inspection of composites possible without signal averaging.

4) Though only two select frequencies were investigated in this case, the example begins to show the capabilities of BAT® transducers for air-coupled ultrasonic resonance spectroscopy work in general. This is possible either with toneburst drive and scanning through a range of different frequencies, or by using a chirp drive for obtaining full spectrograms in real time. This ability to undertake spectroscopy work in materials is a significant advantage of the BAT® technology for non-contact NDT.

5) Unlike other air-transducers available (which have much narrower frequency bandwidths), MicroAcoustic's BAT® transducers can be used with a wide variety of materials and material thickness without the need to change transducers. This saves time and money, since only one set of BAT® transducers are required for most of your inspection needs.

<< previous example ~ next example >>

www.microacoustic.com