home

> products

> BAT's

> BAT

examples

> example B.1.c

Air-coupled inspection of bond-line thickness in aluminum lap-joints using BAT® transducers

The experiment:

MicroAcoustic

BAT™ transducers have proven capable of making many important

non-contact measurements of bonded multi-layer structures, including

bonded aluminum lap-joints of great interest in the aerospace

industry. In this example, two non-contact BAT-1

transducers were used in a normal-incidence through-transmission C-scan arrangement

in order to image and characterize variations in the bond-line of a

carefully prepared aluminum lap-joint sample. The transducers in this case were placed a

distance of ~10cm apart in a coaxial configuration, and with the normal of

the lap-joint sample parallel to the transducer axes. The source transducer was

excited into vibration by a ~400V

p-p toneburst voltage, whose frequency was altered from scan to scan so as

to produce a series of C-scans at different toneburst frequencies. The toneburst

frequencies selected were

chosen to lie in a range that matched to a certain type of longitudinal

"mass-spring" resonance within the lap-joint structure.

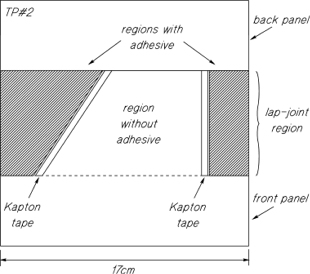

The lap-joint sample was manufactured by the Institute

for Aerospace Research (IAR) at Canada's National

Research Council using two identical 1.58mm thick aluminum panels. The

front panel was made to overlap the back panel by more than 50% of their

surface areas in order to form the lap-joint region shown in the figure at

right. FM73 Cyanimid film adhesive (of nominal thickness 150µm)

was employed in the lap-joint region to bond the panels, though a large

trapezoidal region in the center was purposefully left without adhesive to

create a perfectly disbonded region. In order to limit the spread of

adhesive into the disbond region during subsequent processing in an

autoclave, Kapton tape dams were employed as shown along the bond/no-bond

lines. Best efforts were made by those with much expertise at IAR in

creating such samples to keep the adhesive layer thickness as uniform as

possible. But even with such care and experience, thickness variations of

the bond line were still present after manufacture (a fact that is rather

telling of the likely state of bond-line uniformity in actual lap-joints

of aircraft and other engineering structures).

The lap-joint sample was manufactured by the Institute

for Aerospace Research (IAR) at Canada's National

Research Council using two identical 1.58mm thick aluminum panels. The

front panel was made to overlap the back panel by more than 50% of their

surface areas in order to form the lap-joint region shown in the figure at

right. FM73 Cyanimid film adhesive (of nominal thickness 150µm)

was employed in the lap-joint region to bond the panels, though a large

trapezoidal region in the center was purposefully left without adhesive to

create a perfectly disbonded region. In order to limit the spread of

adhesive into the disbond region during subsequent processing in an

autoclave, Kapton tape dams were employed as shown along the bond/no-bond

lines. Best efforts were made by those with much expertise at IAR in

creating such samples to keep the adhesive layer thickness as uniform as

possible. But even with such care and experience, thickness variations of

the bond line were still present after manufacture (a fact that is rather

telling of the likely state of bond-line uniformity in actual lap-joints

of aircraft and other engineering structures).

The resulting images:

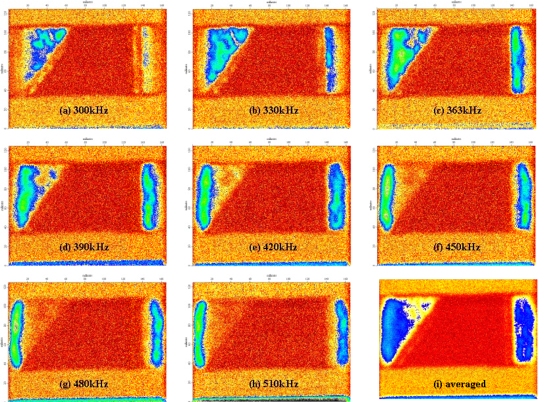

The resulting C-scan images above

are typical of the excellent results that can be obtained by MicroAcoustic's

BAT® transducers when investigating bonded aluminum

lap-joint structures without contact. Except for image-i at

bottom-right, these

images were obtained by exciting the BAT®

source transducer at different toneburst

frequencies ... starting at 300kHz in image-a (top-left) and

increasing in 30kHz

increments in a left-to-right/top-down order through to 510kHz in image-h

(bottom-middle). Image-i is not a C-scan but a pixel-by-pixel average

of all the other C-scans. The dark-orange trapezoidal area in the

center of each image indicates the area of lowest through-transmission, and

corresponds with the region of the sample that contained no adhesive

whatsoever (i.e., the simulated perfect disbond). The light-orange regions on

top and bottom of the images are the regions on either side of the

lap-splice where only one layer of aluminum was present. To the right and

left of the central disbond are the regions containing adhesive of varying

thickness. Here, dramatic increases in through-transmission

(blue-green-grey) occurs wherever the applied toneburst frequency matches

the longitudinal resonance mode of the Al/bond/Al structure. The regions of

high-transmission nearest the central disbond at low frequency are seen to

shift toward the outer edges of the sample as the frequency increases. This

occurs because the bond-line thickness is greater nearest the central

disbond and thinner toward the edges. Theoretical modelling of the resonance

of the Al/bond/Al structure allowed bond-line thickness in the

high-transmission areas to be estimated from the C-scan images: 360µm,

300µm, 245µm,

210µm, 185µm,

160µm, 140µm

and 125µm

for images a through h respectively. The fact that these

measurements of bond thickness agreed with independent measurements by a

machinists contacting micrometer are impressive. The pixel-by-pixel average

of all C-scans (image-i) is of interest since it proves that all

areas in which adhesive were present were well-bonded despite thickness

variations being present. Image-i also provides a warning to users of

narrow-bandwidth air-coupled transducers, for such a transducer operating at

a center frequency of 510kHz, say, could only have produced an image like

image-h and thereby led the user to the incorrectly conclude that

only the outer-most edges of the adhesive regions were well-bonded.

Conclusions:

1) This example shows that MicroAcoustic's BAT® transducers provide a practical non-contact alternative for the inspection and characterization of bond-lines in multi-layer structures such as bonded aluminum lap-joints. This is a relatively important result for the aerospace industry, partly because bond-line thickness is thought to affect strength and fatigue-life of lap-joints that form the skins of aircraft, but also because non-contact inspection methods are required in this industry for practical and economic reasons.

2) Because of their wide

bandwidths, BAT®

transducers allow tuning of toneburst drive frequencies to match nominal

through-thickness resonances of bonded lap-joints. This in turn avoids the

incorrect and costly conclusions that would otherwise result from the use

of narrow-bandwidth air-transducers as to the local state of bonding or

disbonding within the lap-joint.

<< previous example ~ next example >>